Insley Soft Packing Co., Ltd. was founded in 2018 Xiamen Tongan China, where is a Overseas Chinese and Taiwanese ancestors 'place.The core activities are soft packing and providing production, consulting services and matieral to enterprises.

We invested CNY 80 million in R&D and Production.Covering an area of 6600 square meters,it has a standardized production workshop, laboratory, warehouse and comprehensive office. The production equipments in various advanced from Oversea and domestic, Such as 2 automatic high-speed printing production lines for electronic axes (9-colors printing machine),Shan-Zhang high-speed dry-rewinding machine, Italy Nordemick high-speed solvent-free compound machine, two cutting production lines, automatic spraying code platform and high-speed inspection machine; Wuxi Tiemin high-speed bag making machine, Shanghai Gaoqin high-speed bag making machine, The scope covers pharmaceutical packaging materials, food packaging, cosmetic packaging, daily chemical packaging, etc. The product types include roll film, cover film, three-side sealing bag, organ bag, zipper bag, tote bag, upright bag, four-side sealing bag, octagonal sealing. High-tech private enterprises that produce and sell bags, shaped bags and high-temperature retort bags. Specialized in flexible packaging solutions for pharmaceutical, food, daily chemical, beauty and other industries; first-class technical management personnel and a sound internal management system;

The company always adheres to the "artisan spirit", keeps pace with the times, and constantly develops and innovates. Yinshili is committed to making packaging a first-class green flexible packaging production base. Yinshili is more than just a flexible packaging supplier, it is a partner that offers more competitive partners and consistent quality and service.

If you are interested in any of our products or would like to discuss a custom order, please feel free to contact us, we are looking forward to forming successful business relationships with new clients around the world in the near future.

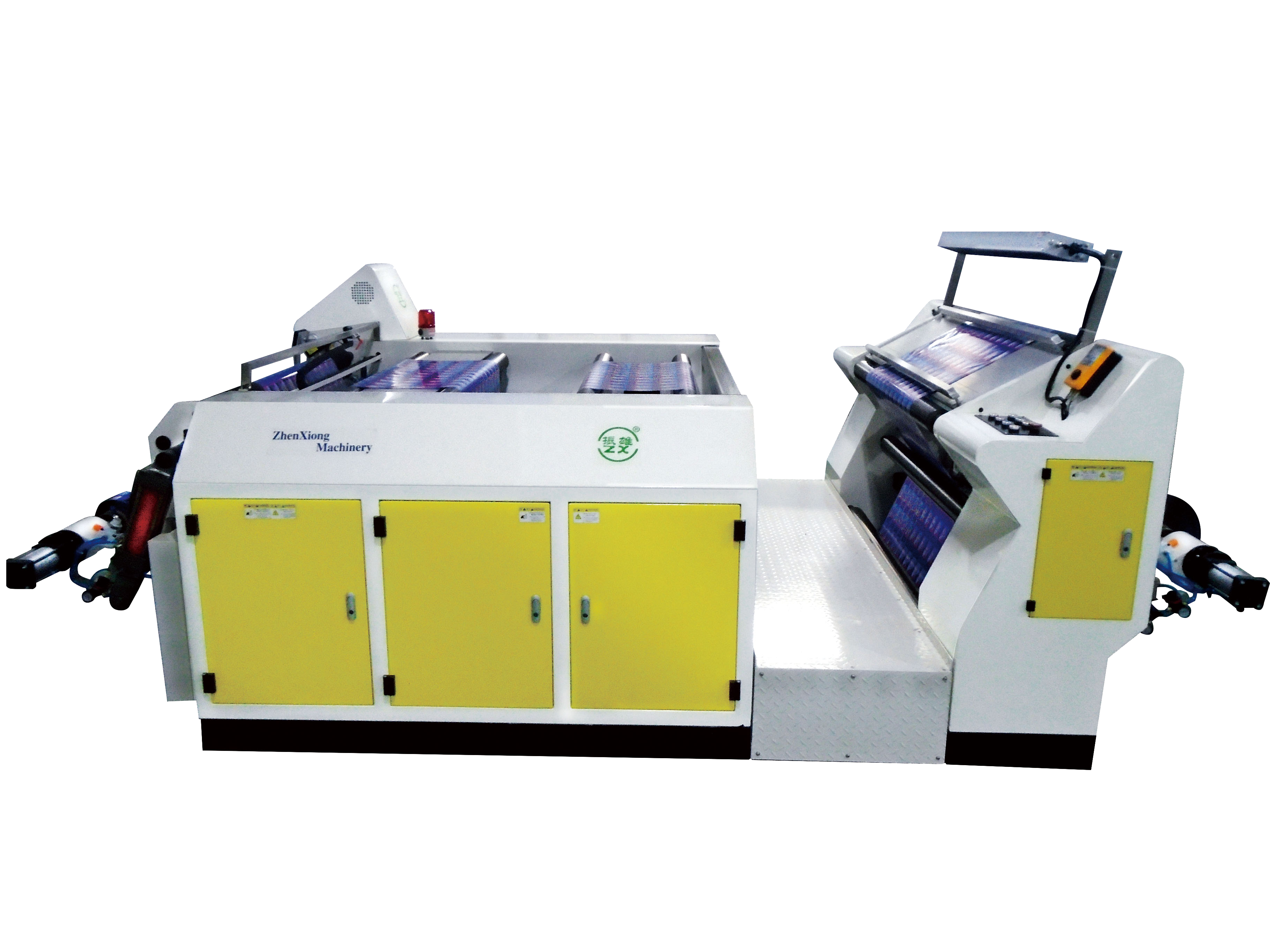

Electronic shaft high speed gravure color printing machine

Printed in strict accordance with the CMYK standard color, in the constant temperature workshop to adjust the ink viscosity, lead to the most saturated color difference, to win the best start for customers on the packaging; the product is suitable for a variety of roll plastic film, aluminum foil, reel Multi-color continuous printing of paper. The equipment is reasonable in structure, easy to operate, and accurate in overprinting. It is a high stability and high efficiency printing equipment.

High-speed inspection rewinding machine

Yinshili uses the innovative technology to accurately control the size and amount of the external packaging, and presents the high-quality products to the customers as much as possible. The equipment is equipped with the procedures of correcting and unwinding, pulling, trimming and winding. The hydraulic system, stroboscopic detection system and three-servo tension control system are combined to form a stable, reliable and convenient human-computer interaction.

Computer automatic high speed dry laminating machine

Yinshili uses the innovative technology to accurately control the size and amount of the external packaging, and presents the high-quality products to the customers as much as possible. The product is suitable for the compounding of various reel plastic films, aluminum foils and webs. . The equipment has reasonable structure, simple operation, smooth material and stable tension, and is a high stability and high efficiency printing equipment.

Nordmec solvent-free laminating machine

The company has Germany's most advanced Nordmec solvent-free laminating machine, which combines the advantages of higher running speed, lower energy consumption, less binder consumption, better return on investment, etc. Less, no risk of fire and explosion. 100% binder, no solvent residue, reducing the pollution of packaging contents, especially food, medicine and so on.

High speed horizontal slitting machine

Yinshili uses the innovative technology to accurately control the size and amount of the external packaging, and presents the high-quality products to the customers as much as possible. The equipment sets the rectification, unwinding, towing, slitting, winding, and waste collection. (Can also be blown), automatic discharge, rotary unloading and other processes are completed at one time; the machine has a series of advanced designs such as high speed, stable performance, flexible winding shaft winding, etc. The system adapts to the tension demand of different materials, and is currently wide Ideal for slitting material.

High-speed inkjet labeling and rewinding machine

Yinshili uses the innovative technology to accurately control the size and amount of the external packaging, and presents the high-quality products to the customers as much as possible. The equipment sets the rectification, unwinding, drawing, coding, labeling, inspection, The winding and other processes are completed once; the machine has high speed, stable performance, and hydraulic loading and unloading materials.